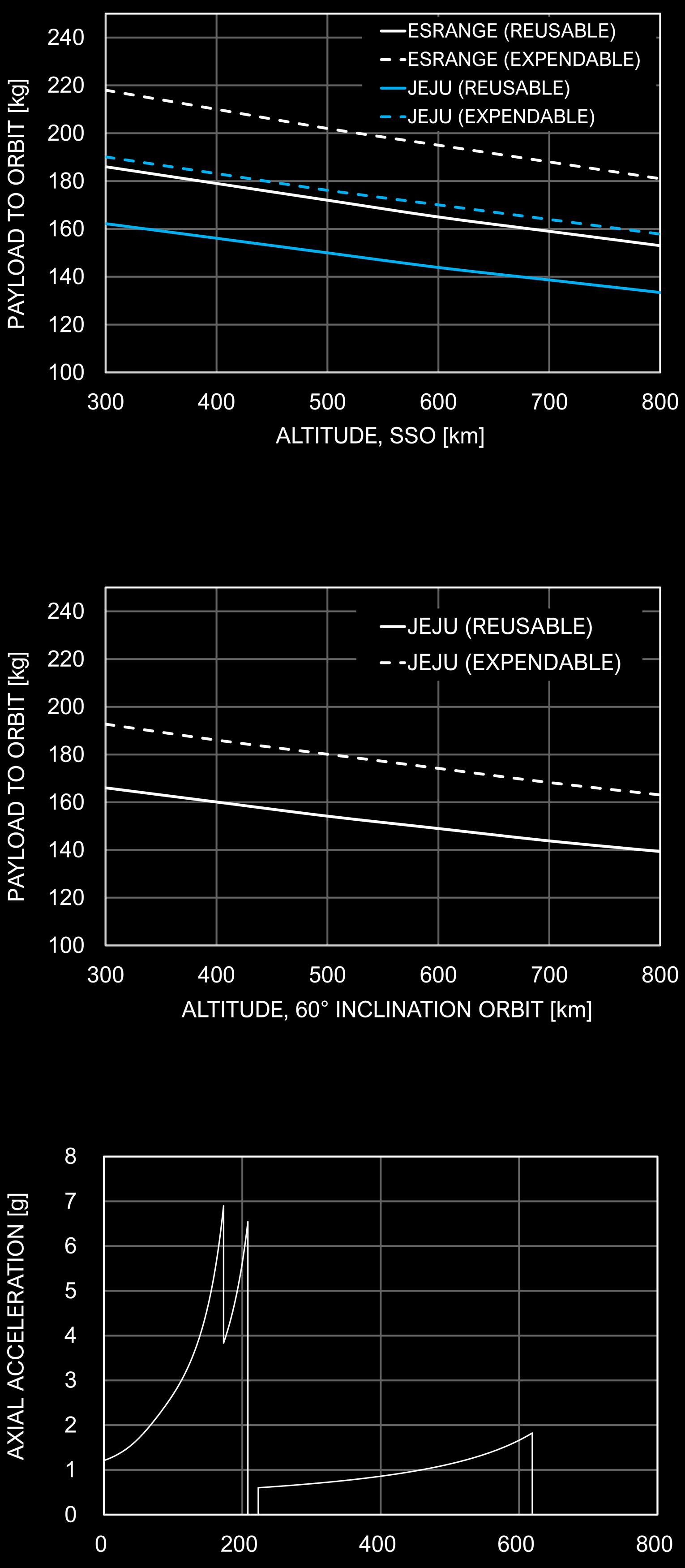

Blue Whale 1 is a two-stage orbital launch vehicle capable of placing a 150 to 200 kg payload into a 500 km Sun-Synchronous Orbit with the fully reusable first stage.

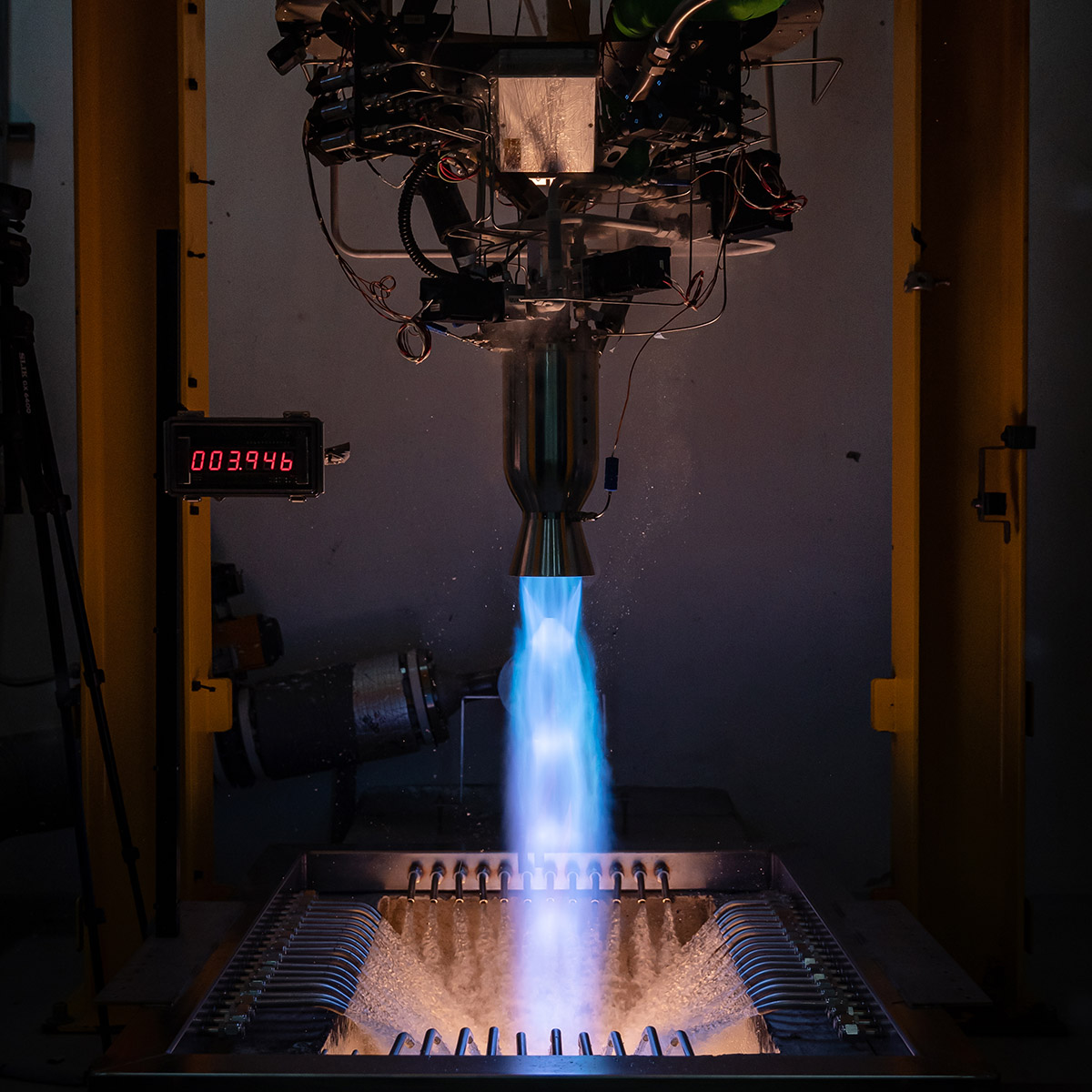

By using liquid oxygen and methane as propellants for both stages, BW1 emits far fewer carbon pollutants into the atmosphere. It also enables higher engine performance and better maintainability. For lightweight construction, Blue Whale is mainly constructed from high-strength carbon composites, improving payload mass fraction for such a small and lightweight launch vehicle.

The flight test program will begin in early 2025, followed by commercial flights in 2026. With a total launch price of less than $3M, it is the most affordable launch vehicle in the world.

By using liquid oxygen and methane as propellants for both stages, BW1 emits far fewer carbon pollutants into the atmosphere. It also enables higher engine performance and better maintainability. For lightweight construction, Blue Whale is mainly constructed from high-strength carbon composites, improving payload mass fraction for such a small and lightweight launch vehicle.

The flight test program will begin in early 2025, followed by commercial flights in 2026. With a total launch price of less than $3M, it is the most affordable launch vehicle in the world.

Blue Whale 1 Specification

| PAYLOAD TO 500 km SSO | 170 kg |

| PAYLOAD TO 500 km LEO | 150 kg |

| LAUNCH MASS | 19,800 kg |

| DRY MASS | 1,510 kg |

| TOTAL LENGTH | 21.0 m |

| NOMINAL DIAMETER | 1,600 mm |

| THRUST AT LIFTOFF | 260 kN |

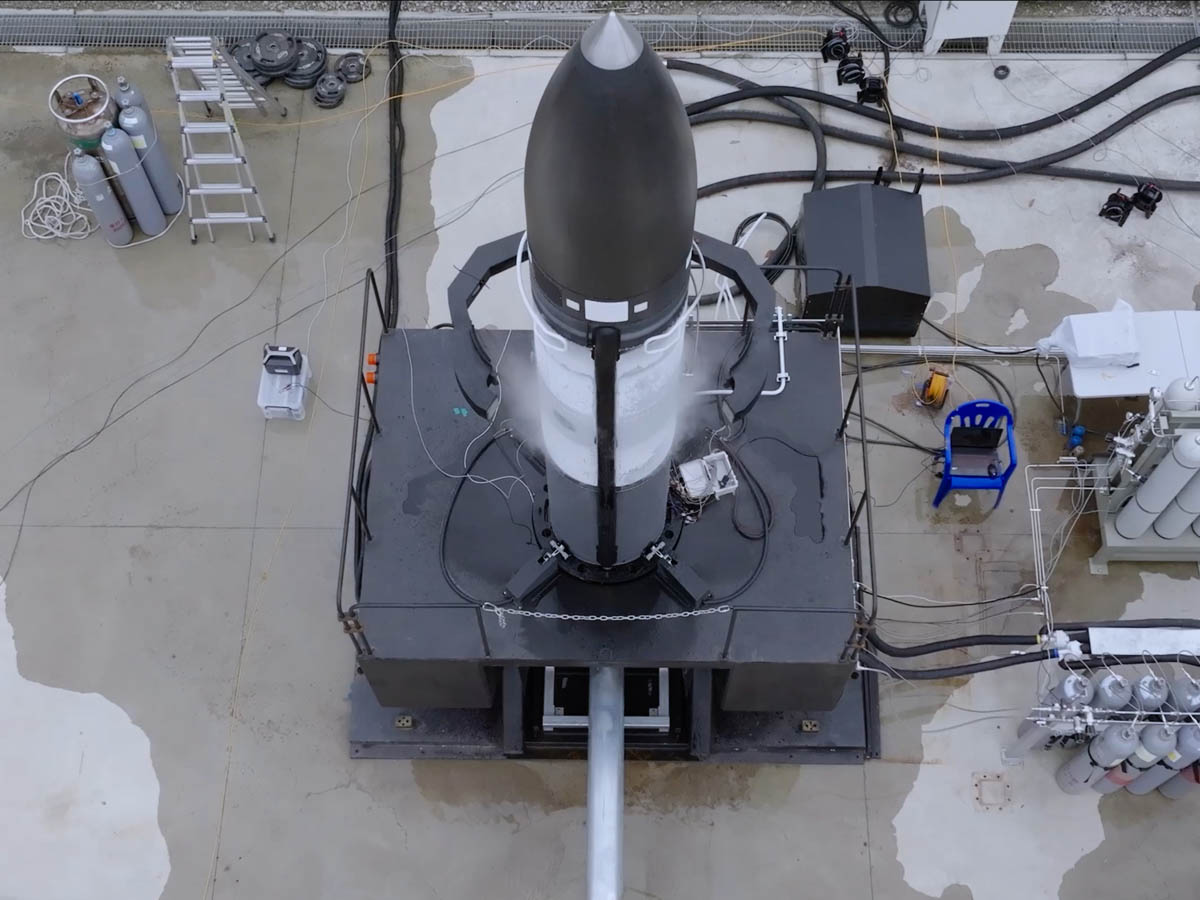

Since 2021, the Jeju Launch Center has been the home stadium for Perigee.

Since 2021, the Jeju Launch Center has been the home stadium for Perigee.

The Esrange Space Center, located in northern Sweden, is Europe's top launch site that has conducted over 600 sounding rocket launch missions in the past 60 years.

The Esrange Space Center, located in northern Sweden, is Europe's top launch site that has conducted over 600 sounding rocket launch missions in the past 60 years.